Even More Banjo Work -- Resonator |

This is more on my cheapo open-back 5-string Rogue banjo from you-know-where. The saga of me getting to this banjo is too long to tell. But I have it and I want it like I want it. And then one day in a fit of unqualified and unjustified enthusiasm I decided I wanted to make a resonator for it. |

I didn't care for the 14:1 guitar tuners on it so I got some decent 4:1 tuners. They work much better. I had some screw holes to patch from the 14:1s so I gave the back of the peg head a shot of favorite GMC crankcase red-orange paint. |

I had cut a disc from two pieces of 3/4" ply for a 1-1/2" thick form and I cut one disc of 1/8" birch aircraft ply for the resonator back. I cut a bunch of strips of 1/16" birch ply to wet and shape around the thick ply form. I had done this many times before, but back then I was drying it in a microwave oven. I couldn't that this time so this was more difficult to do right. Here they are drying. |

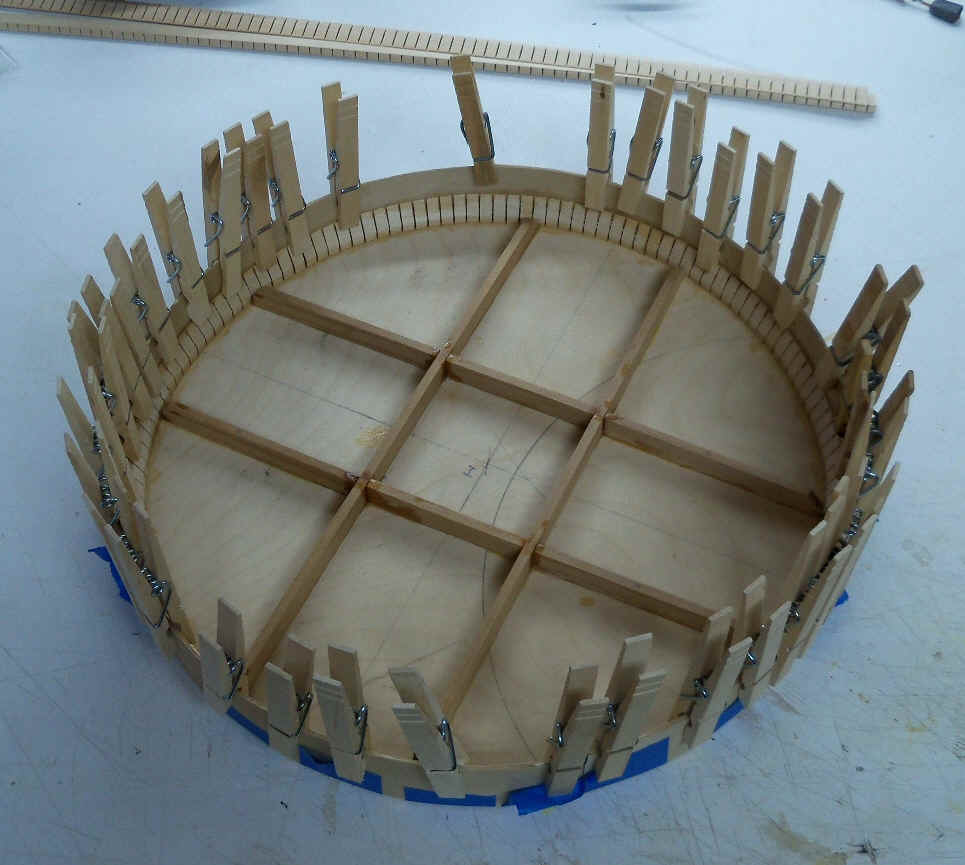

I used some spruce to glue directly to the inside (bottom) of the 1/8" back. I thought it needed the bracing -- I still do not know if it did. It would work and sound the same either way I guess. Then I used some bracing from Stew-Mac for the rim. I used Titebond when I was not in a hurry. I used CyA when I was. Here, the first round of 1/16" is glued to it. |

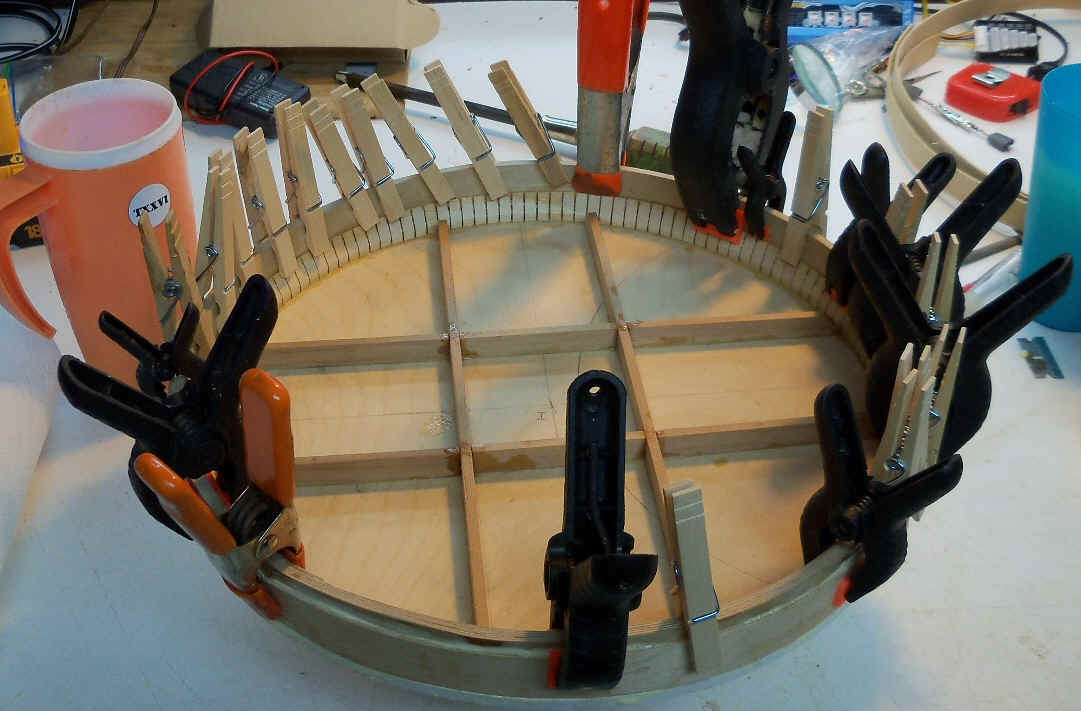

Then I started building up the sides with more strips of 1/16 brich. I used Titebond. |

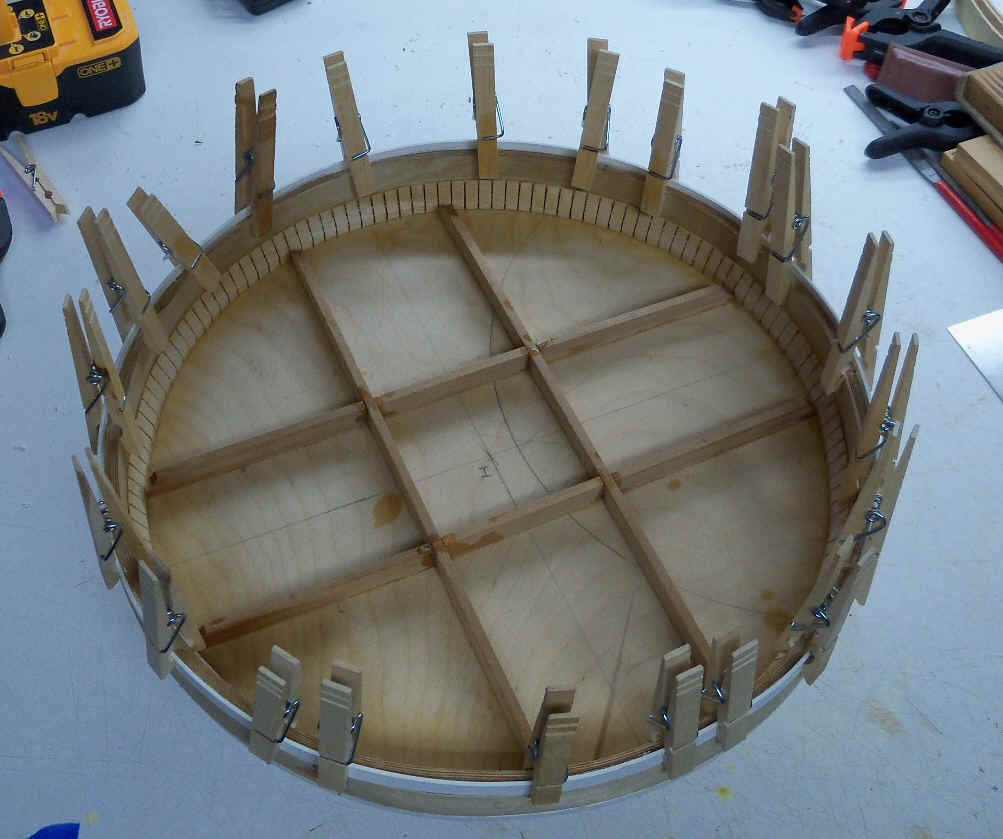

When I had the number of plys that I wanted, I rounded it as good as I could. Then I could put the last ply on, but this last one would be less wide because there must be enough space for my binding on both edges of the resonator.

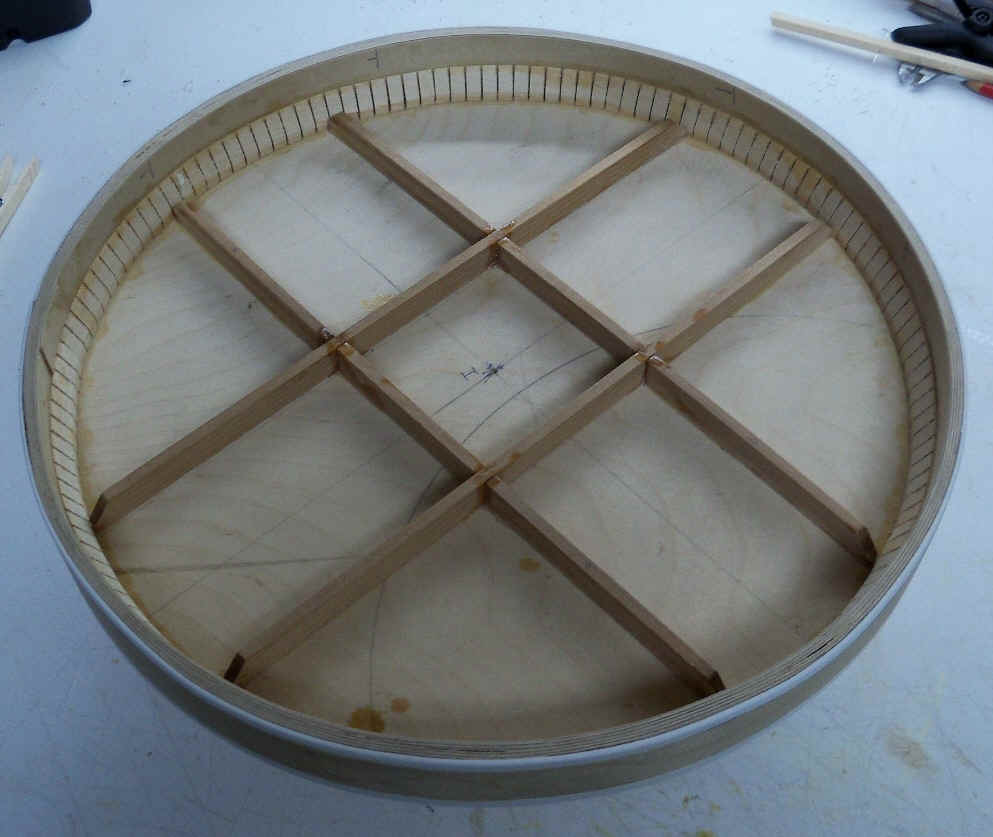

Now there is the wider white binding in place. This is the bottom.

The final ply is being added against the bottom binding. (Is there any guy with enough clamps?)

With the last ply dry, I added the top binding. I wanted it to protrude past the resonator top edge so I could have it level when trimmed down..

Both bindings are on and trimmed properly for width. It needs a little filler and finish.

The resonator portion is pretty much complete here. It looks OK and it is stiff. Now I need to figure out how to finish it and secure it to the banjo.

This shows the banjo internal rod and the bottom of the head. I fabricated an aluminum plate and drilled and tapped it and this is close to the way it ended up. I am pleased with how secure it is. The vertical bolt will barely protrude from the resonator so I can put a bakelite thumbscrew on it.

Note: Since I do not play banjo, I do not remember what the strings are tuned to. I have this written inside -- and I tune in "C". After I put the resonator on, I had to write the tunings on the head rim so I could see that when tuning.

The unfinished 1/2" ply braces are numbered because they are cut to fit snuggly from resonator rim (where they are glued with Titebond) and there is black felt between these braces and the banjo rim holding the banjo rim in compression to the resonator. The inside of the resonator is now painted flat black, as were these spacers. I had made the arm rest from some model airplane trophy I won back in the '80s. Those are my first sources of good wood.

The tuners look nice and work well.

The resonator is on the banjo. This is the same GMC crankcase color. The knob only protrudes 1/4". I wanted the back stained red mahogany, but birch does not take dark stain well and I didn't want to do my trick of mixing various sealers to put on before the stain. I just kept telling myself: "Hey! It is but a banjo!" This recognition cuts down on the amount of time I would be spenidng on it.

I need to tighten up the screw on my tuner. I had to extend the feet of the bridge with 1/8" solid maple (on three feet) to increase string clearance to stop fret buzz. The black square is a piece of adhesive felt on the head so my finger picks will not click on the head. That is where I generally play. The head was tightened according to Dan at Stew-Mac. I guess now I will put the 5th string capo back on -- then I can play in C and D. ("There is small choice in rotten apples." -- Shakespeare; The Taming of the Shrew.) Now I will start working on what all banjos need; a variable mute. I have several ways of doing this and this will be easier done than this resonator. "Hey! It is but a banjo." |

| N |